Screening and Separation

-

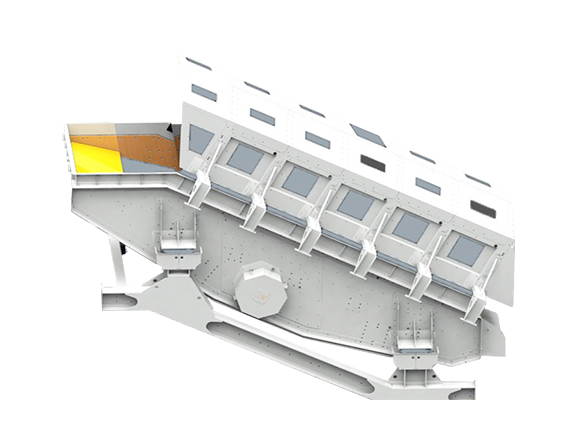

Ballistic Vibration Sortor

Adopting the imported German crankshaft mechanism transmission, ballistic screen can sort the materials into three categories and bounce off the materials attached to the package to achieve an unparalleled sorting effect.

Email Details -

Ballistic Screen

Adopting the imported German crankshaft mechanism transmission, ballistic screen can sort the materials into three categories and bounce off the materials attached to the package to achieve an unparalleled sorting effect.

Email Details -

Ballistic Sortor

Adopting the imported German crankshaft mechanism transmission, ballistic screen can sort the materials into three categories and bounce off the materials attached to the package to achieve an unparalleled sorting effect.

Email Details -

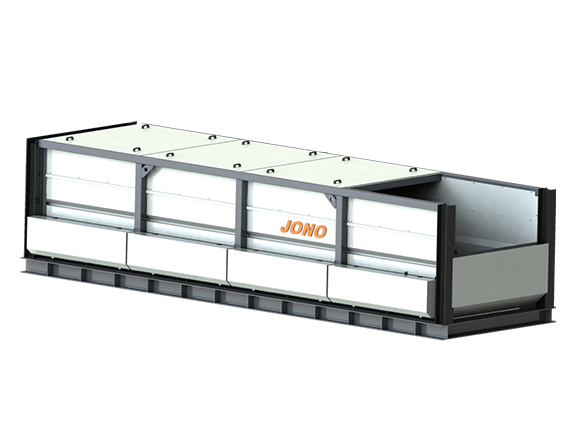

Trommel Screen

Trommel screen is designed to effectively separate MSW, organic waste, recyclable waste, stale waste and kitchen waste by different drum screen sizes to optimize the material for the subsequent processing. JONO trommel screen can clean itself while working as it rotates,which maximize the separating efficiency and lessen the maintenance work.The high efficiency and the high quality will highly profit you in a long run time.

Email Details -

Disc Separator

As one of the most important sorting machines, disc screen separates material into big-sized material and small-sized material. By changing the screening size, you can always separate out what you need.Typically,it is applied in treating MSW,in process of which organics or RDF can be well separated out.

Email Details -

Stepped 3D Screen

The stepped 3D screen is for large-sized materials. The JONO stepped 3D screen is carried out as a vibrating screen with a circular motion and is driven by a high-performance and equally energy efficient three-phase AC motor. The blind bottom on the infeed side guarantees an efficient utilization of the screening surface, a good material flow,increases the servicelife of the screening elements and reduces blocking material. The screening elements can be changed easily and quickly and are therefore easy to adjust to the different sized cuttings.

Email Details