AI Visible Light Sorting

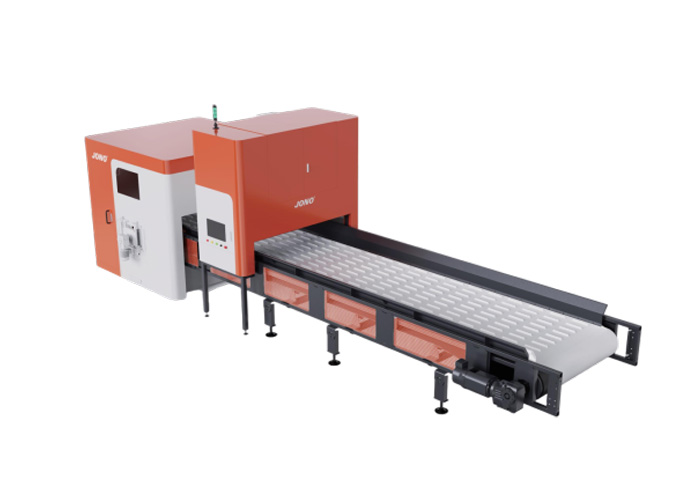

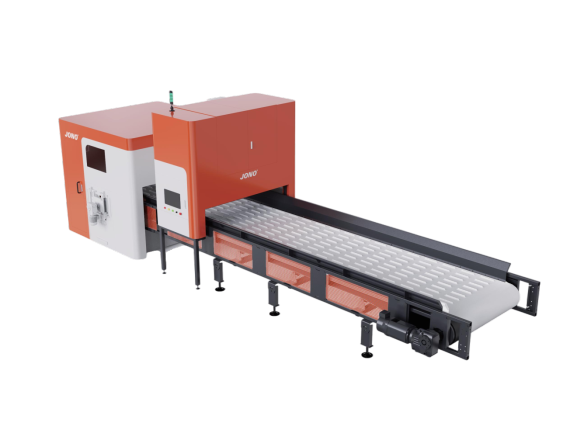

- JONO

- China

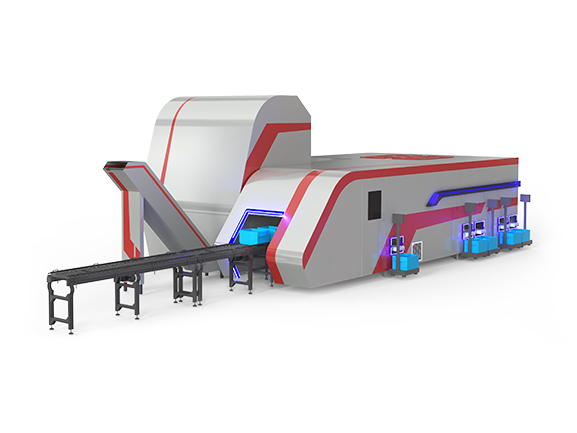

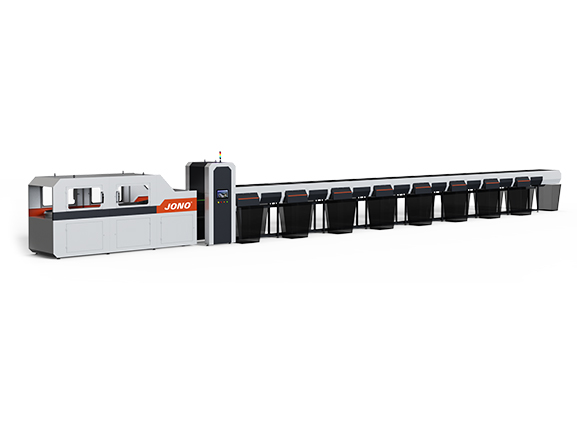

AI Visible Light Sorting Machine is widely used in the processing system of color and material sorting of various recycled plastics, with fast sorting speed and wide sorting range. It can simultaneously realize the identification and sorting of 3A bottles, 4A bottles, 5A bottles, oil bottles, original color HDPE bottles, colored HDPE bottles, miscellaneous plastics, PP lunch boxes and other plastic materials. With JONO's unique solid waste database, it can realize fast switching of product application scenarios.

JONO's self-developed and original AI intelligent identification system, combined with the large database of solid waste accumulated by many waste treatment projects of JONO, can achieve accurate identification under the high-speed conveying condition of 4m/s.

The visible light sorting technology developed by JONO can achieve more accurate color sorting than the naked eye and high-definition color camera by accurately identifying multiple characteristics of materials such as color, size and shape, and combining the visible spectrum with the invisible spectrum of infrared and ultraviolet light.

Using high-speed scanning system, it can accurately obtain the multi-dimensional characteristics of the materials on the high-speed belt, and achieve accurate identification under the high-speed conveying conditions of 4m/s.

Support visible light, near infrared, X-ray, fluorescence, laser, hyperspectral, metal detector and other combinations of sensors, according to the material situation for multi-dimensional identification determination

Features

High sorting rate: rich sample database, innovative intelligent image recognition technology, combined with self-developed algorithm models for different recycled plastics and other complex materials, greatly improve the sorting accuracy, the sorting rate could reach more than 98%.

High flexibility: simple operation interface, quickly switch to select different material library by one click, to achieve sorting a variety of materials at the same time.

High efficiency and stability: High efficiency motion control system ensures high speed and stable operation of the equipment.

High intelligence: computer cloud based self-learning ability, remote diagnosis and intelligent upgrade functions.